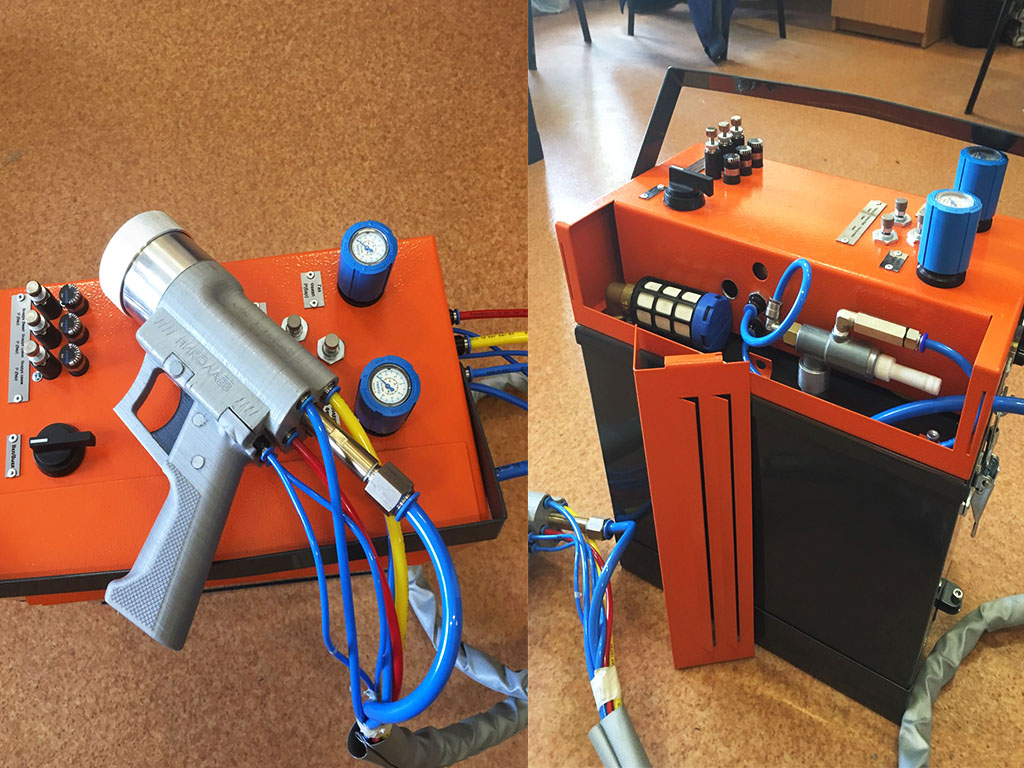

Installation of Portable Gas Flame Coating (FLAME SPRAY)

WHAT IS FLAME SPRAY?

FLAME SPRAY paint technology is a paint application technology that has been developed as a result of R & D studies which have been going on for many years in a period of more than 15 years. FLAME SPRAY is a technique that combines heat, paint and air on the application surface and it is a technology with many different materials and techniques which vary according to the application areas. When the materials, places and external factors to be applied are analyzed correctly, they have a structure that protects itself and the covering floors for many years when the preparations before the application is made completely.

FLAME SPRAY paint machine is a device that has been designed with the application areas, places and conditions in mind, and it is a device that can be carried by hand, which is called as spray gun or machine, and which provides ease of use, a mechanical and physics combination. It has a special place in the sector thanks to its paint properties which are in accordance with its own working principles. Different geometric shapes can be applied in different environments. High adhesion and flexibility is the most prominent feature. FLAME SPRAY protects the surfaces not only from the effects of temperature, impermeability, wear and tear, but also from solar radiation (reflects 90% of radiation), rust, moisture and condensate. FLAME SPRAY is insensitive to temperature and humidity changes and is sufficiently resistant to basic corrosion protection.

Operating principle of portable gas flame installation:

Combustible mixture of propane, compressed air and polymer powder are fed to the burner. Pressurized air coming out of the blowing channel at a high speed pulls the powder with the injection method. The powder burner melts in the flame and encounters the face of the material with great speed. This results in high adhesion.

ADVANTAGES OF FLAME SPRAY COATING

- Thanks to its excellent reflective and diffusive properties, it is highly effective in preventing the transmission of radion energy in isolated structures and equipment. It reflects or re-emits 99% of the energy that comes into contact with the product, so only 1% of the heat emitting energy contacts the structure or equipment.

- Very common method is used for ease of application (up to 150 m2 per day can be applied with a gun as easily as paint)

- The application is the only application technology in the world, which makes the solid paint material used in the second one-second as much as one-half-time into liquid and become solid again in one second.

- It is environmentally friendly and does not contain harmful substances for human health, but it has the hygiene to be applied even on the applied surfaces. Safe chlorides do not contain organic volatiles and heavy metals.

- It is extremely light and flexible. Thus, the surfaces to be applied can be expanded and improved.

- Application thickness is very low and may vary from 0.5 mm to 2 mm.

- Reduces capital and operating costs in applied projects.

- It has a long service life without loss of performance during the operation (10 years).

- It protects the structures that have anti-vandalism properties.

- It is sound and vibration inhibitor.

- It is sensitive to humidity and temperature changes with its high protection against corrosion.

- In the case of changes in the colors applied over time, different colors can be applied to the previously painted surfaces without any preliminary work.

Main Features of Flame Spray:

1. Long-term adhesion coating without paint primer

2. Highly resistant to salt and ultraviolet rays

3. Does not give any harm to food or water components

4. Low smoke / toxicity rate during combustion

5. Elongation of high flexibility 500-700%

6. Lack of blowing / cracks

7. Operating temperature range up to +70 C -70 C

8. Resistant to chemicals

9. Suitable for sea water environments

10. Paintable surfaces: mdf, concrete, wood, iron, glass, etc.

|

Painting Capacity |

Kg/per hour |

3-3,5 |

|

İf Thickness is 250 micron |

Square meter/per hour |

8-10 |

|

Size of Powder Particles |

micron |

150-350 |

|

Coating Thickness |

mm |

0,15-3 |

|

Storage Capacity |

liter |

10 |

|

Propane-Butane Gas Expense |

m3/per hour |

1,2 |

|

Compressed Air Expense |

m3/per hour |

36 |

|

Propane-Butane Gas Working Pressure |

bar |

1-1,5 |

|

Working Pressure of Compressed Air |

bar |

3-4 |

|

Product Mass |

kg |

15 |

|

External Dimentions of the Product (length/width/height) |

mm |

400x200x500 |

APPLİCATİON AREAS

INDUSTRIAL BUILDING APPLICATIONS

* Steam hot water pipes

* Ventilation pipes

* Gas tanks and pipes

* Hot oil tanks and lines

* Petrol diesel tanks

* Oxygen lines

* Oil pipelines

* Water tankers

* Cement and nitrogen storage tanks

* Oil separators

* Chemical hot mixing tanks

* Steam and oil boilers

* Medium and high pressure steam lines

* Agriculture and food industry

BUILDING CONSTRUCTION APPLICATIONS

* Cold weather depots

* Roof batons

* Building roof and walls

* Roof sealing liners

* Silos

* Metal buildings

* Hangars

* Garages

* Military facilities

* Industrial chimneys

* Aerospace defense

* Refrigerator and freezing system equipment

* Steel construction structures

* Garage workshop areas

VEHİCLE APPLİCATİONS

* Tankers

* Railroad wagon outer compartments

* Boats

* Steel safe

* Metal case floors