TEKNİKEL-MAKİNE

We are always ready to serve for our valued customers!

One of the most important elements required for quality powder painting is cleanness of the surfaces. Fouling of surfaces causes some imperfections in coatings. It also decreases the paint retainer. Chemical pretreatments should be preferred for corrosion protection. Degreasing, Solvent Dip, Zinc Phosphating, Chromatization, Filiform are some of the methods. Metal types and quality, surface condition, usage areas of painted products, economic elements should not be ignored. The main target of infrared rays is the molecules in the paint. The definition of our technology is the ability to change the vibration states of molecules in the paint. This feature means that the atomic parts in the paint move very fast forward and backward. The Molecules under the Infrared rays influence react to the light as soon as possible and react with one another. Determination of energy values by considering the effects of the chemicals to be used in the production of paint furnaces and their effects on the determination of the reaction energies is an important fact. Just giving heat doesn’t mean having a good paint application. At the same time, the rays penetrate the surface of the material, allowing them to warm up very quickly and have no communication with the air in the environment. The workning principle of industrial infrared ovens differs from convectional ones. We do not heat enviroment, we heat the material itself. Therefore, the temperature measurements should be made on material. The technology used in our ovens (lamps) is the most appropriate application method for QUALITY, SAVINGS, TIME, PROFITABILITY.

The principle of infrared radiation drying and dehumidification is based on distinguishing itself from other applications. All of the other applications consist of such facilities like creation of the temperature in the oven only and ensuring the materials under this temperature for a certain period of time. However, such applications can give bad results because sometimes drying process depends on the thickness of the material and the quantity of moisture in the pores of the material or in the bended corners. Although these problems are not seen in the production stages in short time, afterwards the natural tissues of products can change, the removal of paint, fade, yellowing can appear. The energy source in infrared radiation works through the invisible light to the middle of the material without losing the energy, the material consumpts the given energy and starts to spread in it rapidly. If the drying is done by hot air up to 100 degrees, the material can be supplied with 750 kcal / m2 but under the same conditions with infrared radiation this number is about 22000 kcal / m2. Material quality and thickness are important here. Various applications (surface cleaning) in the material and on the surface of the moisture structure of the existing liquids are evident. In the process of drying or dehumidification, chemical cleaning applications should be taken into consideration during the heat treatment. The aim should be to prepare the dried materials in a healthy way to the next process stage and to increase the quality and efficiency as a result of the processes to be performed. We use special infrared lamps which provide a suitable energy for different types of drying and dehumidification processes.

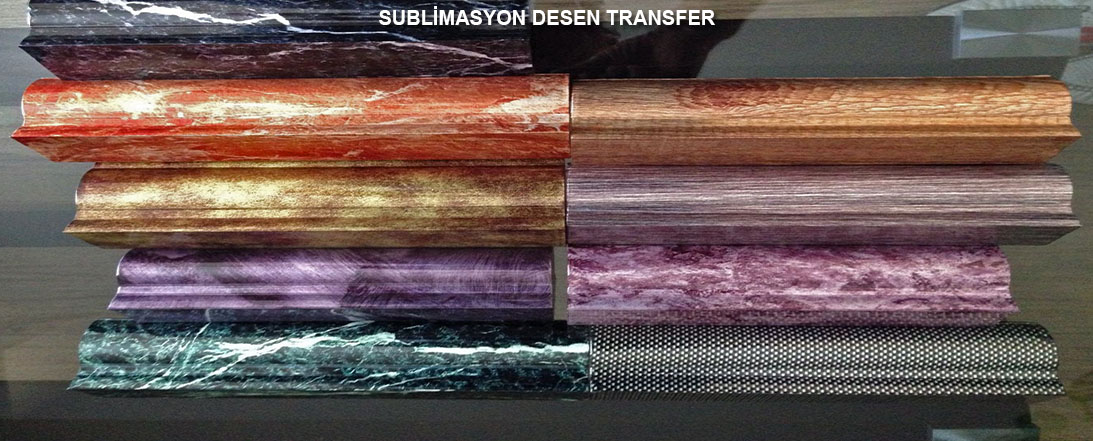

It is a machine designed for transferring the thermoforming pattern of sublimation to the profile and flat materials that are painted with powder paint.

Sublimation Application Materials:

*Aluminum profiles and flat materials

*Metal profiles and flat materials

*Glass sheets

*PVC profiles and flat materials

*MDF panels

Why we?

Infrared Drying Furnace

100% eliminates moisture in drying processesThe heat goes up to the inner layers and focuses on drying the inside moisture

Infrared Paint Curing Oven

Homogenous, fast and energy-efficient curing processSimultaneous drying of multiple colors

Infrared Sublimation Machine

Pattern coating without errors, European standardsPattern pigment goes up to 80 microns into powder coating

Flame Spray

Corrosion-resistant, long-lasting coating with thermoplastic paintHigh resistance against salt and ultraviolet rays

Infrared Powder Coating Curing Furnaces

The Infrared, a single word of 3 different results, SHORT WAVE, MEDIUM WAVE and LONG WAVE; LONG WAVE usage (radio waves), MEDIUM WAVE is considered to be new; it has past approximately 40 years , we still benefit from it (ufo heaters) and SHORT WAVE is known by everyone, we have heard about it’s benefits, power, effect, although we have ideas about what can be used to make this energy technology; infrared mechanisms and inventions have not yet taken place in our lives . Short infrared wavelength while reflecting to any object loses just 15% of it’s energy, while middle wave loses 40% and long wave loses 60% of the energy. From here, it is seen that short wave infrared radiation is more advantageous in terms of energy efficiency. Since the beginning of 2016, TEKNİKEL MAKİNE has been conducting our R & D studies with our expert staff in order to use the energy of SHORT WAVE INFRARED Fatom in many fields. As a result of our completed works, we offer many innovations and improvements in all the machinery and equipment used in our industry, where the heat treatment is between 50-250 Cº. In our CURING and DRYING furnaces, we achieve the results not only by heat treatment but also by playing with wavelengths without disturbing the structure of the material and it’s chemical coating. Our rays work up to the middle of the material and quickly begin to heat both surfaces. Keep in mind that the temperature in the oven has no effect on curing. Direct heating of the material is the right solution.Since our machines are equipped with short wave infrared lamps, it brings differences and innovations on many factors mentioned below. First of all, it doesn’t have any damage to human’s health, no gas emissions are used; it is appropriate to all standarts, no need to take some extra measures. Our technology works with 380 volt industry electric energy and it captures the heat values mentioned. There is no fire section, that is presented in convectional ovens, therefore, there is no problem in the factory. It does not store the heat energy in a single area in high amounts, transfers it to the material in the most effective and short way and starts to consume its energy. The transfer of natural gas use is a risky and expensive energy source. It requires a certain project and serious financial means, such as the cost of shooting a new natural gas line for a medium-sized company, including the project cost between 50 thousand to 150 thousand TL. However, in this technology only the electric energy is enough. Nowadays, the usage of natural gas depends on foreign sources. It is not very difficult to predict future development.

The most important features that distinguish us from old methods are:

- Silent operation;

- No maintenance, no malfunction, no cost;

- It is healthy, does not contain harmful release;

- Rapid reaction, 190 Cº / 18 min;

- Technology life is long – 50 years;

- Does not interfere with air, does not consume oxygen in the environment;

- Extends paint life;

- Improves paint quality, suitable for all types of standards (salt test, adhesion test, etc.);

- Energy saving (up to 30% compared to the convectional ovens);

- Multiple color curing at once;

- Differences in zones +/ – 2 Cº;

- Increased quality after finishing;

- Control of each desired module separately, regardless of the oven length.

Sublimation (Pattern Transfer Furnace)

Another product is the pattern transfer machine known as SUBLİMATION.In fact, there are many similarities to the standart powder coating application. First step in pattern transfer is normal powder coating. Product must have speacial uv protected powder coating layer. When somebody says pattern coating the first thing that comes to mind is foil coating. We also use special films in our technology, but the main target is the penatration of pattern into the powder coating layer. In standart convectional furnaces the pattern acts to the material surface to 20 microns, while in our infrared machines we can process up to 60 microns of 100 micron paint layer, which makes the pattern more vivid and realistic. The most important feature that distinguishes us from other applications is that we can apply this technology to glass also, so we show newness and useful usage of infrared short waves. Due to the physical properties of the glass, it causes cracking when exposed to different temperature values. It is necessary to obtain a homogeneous heat distribution on the glass surface. It is not possible to do this in gaseous systems. The temperature values of each corner of the glass plate should be controlled. The coating on the glass can only be made when the heat values on the glass are equal and reach the desired values.In order to make a pattern coating, the material must be pre-dyed to the color which is the primary color of the pattern. When the glass coating is made, urethane acryl based wet paint is used. Normally this paint is dry in 4 days. This type of glass coating is not preferred. We can cure dry such paint in 40 minutes with a help of infrared short wave emmitters.